14 Pastörisering

Före fermentering

Efter fermentering

Batch vs flaska

| Temp °C | Effekt |

|---|---|

| <60 | Mycket långsam/liten effekt |

| >70 | Snabb nedbrytning av polyfenoler |

När blir maillardeffekten påtaglig?

Dosering:

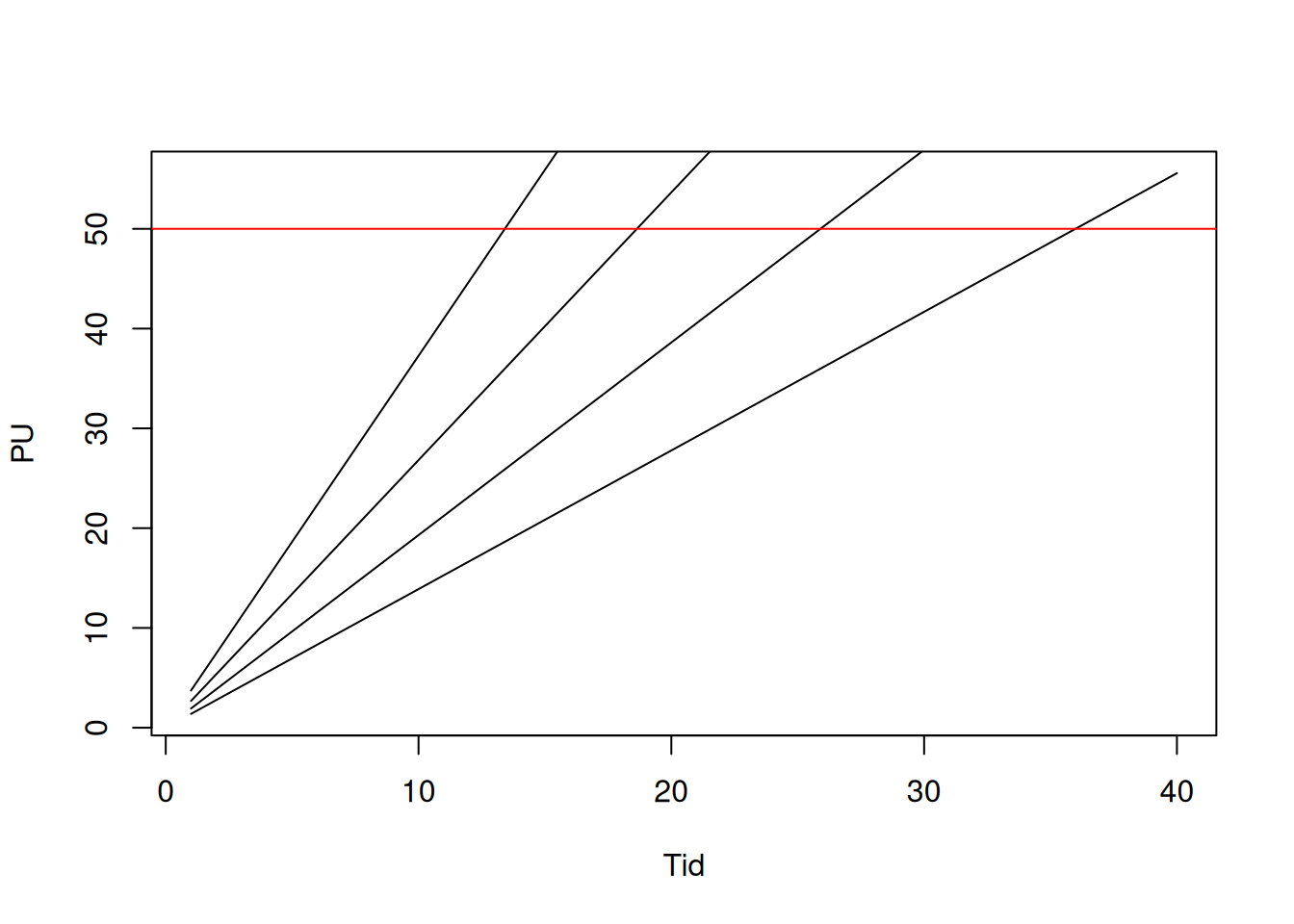

“An alternative to chemical stabilization is pasteurization, which can be performed in batch form or after bottling, depending on available equipment and the presence of carbonation. In-bottle pasteurization allows for carbonation to be preserved, while direct pasteurization of the unbottled product will reduce the carbonation, because the solubil- ity of CO 2 in aqueous solutions is inversely proportional to temperature within the operational range of cider-making. Duration and temperature thresholds determine the effectiveness of heat treatments. Pasteuriza- tion units (PU) are used to define the necessary time-by-temperature interactions in this process, based on the equation PU = t x 10^((T-60C)/z), where t is time in minutes, T is temperature in C, and z is 7C. Cider needs approximately 50 PUs, heated for 50 minutes at 60C or an equivalent time and temperature combination, for a stable product and complete suppression of potential spoilage microorganisms (Duffy and Shaffner 2001). The resultant cider will not be completely sterilized; thus it is necessary to have a low initial microbial load (Mitchell 2006). One disadvantage of in-bottle pasteurization is that it may cause ‘‘cooked’’ or oxidized flavors in ciders; close attention to temperature, time, and free SO 2 levels can minimize these negative effects.”[1]

https://www.homebrewtalk.com/threads/pasteurization-methods-to-stabilize-bottled-fermented-apple-cider.71180/.

14.1 Temperatur och tid

14.2 Dosering

Färdigjäst (klar eller relativt klar) cider: 50 PU.

Päron / högt pH? Högre

Ojäst must: Mycket högre.